After the completion of this module, BTech students in Manufacturing Technology shall be equipped with the essential knowledge and skills required to effectively select materials for manufacturing processes, perform processing of materials, and manage manufacturing waste. Moreover, the successful completion of this module will enable students to make informed decisions regarding material selection, optimize manufacturing processes with efficiency and quality, and implement sustainable practices for waste management in manufacturing environments. By achieving this competence, students will be well-prepared to contribute to the advancement of manufacturing technology while considering environmental and sustainability factors, thereby enhancing their ability to excel in the field and address contemporary challenges in the manufacturing industry.

- Teacher: Notabo Hlabano

This module describes the skills, knowledge and right attitudes required to manufacture products ranging from simple parts to complex parts and learn fundamental principles and practical considerations that enable the production of different parts and assembling at a high scale

- Teacher: Ndahimana Anastase

- Teacher: Gaspard Bizimungu

Dear Students, welcome to this module! In this course, you will learn to design, conduct, and present research, building skills from problem definition to data analysis and reporting. By the end, you will be ready to carry out independent research and apply it to real-world challenges.

- Teacher: Dr.Marie Chantal UWAYEZU

This module provides training in the application of fluid mechanics and thermodynamics within manufacturing systems. It builds on learners’ prior knowledge of fluid flow kinematics, fluid mechanics in machines and processes, mass and heat transfer, and thermodynamic principles. The module emphasizes practical application of these concepts to solve real-world challenges, improve processes, and enhance efficiency in manufacturing environments.

- Teacher: Gaspard Bizimungu

- Teacher: Jean Baptiste NIYIGABA

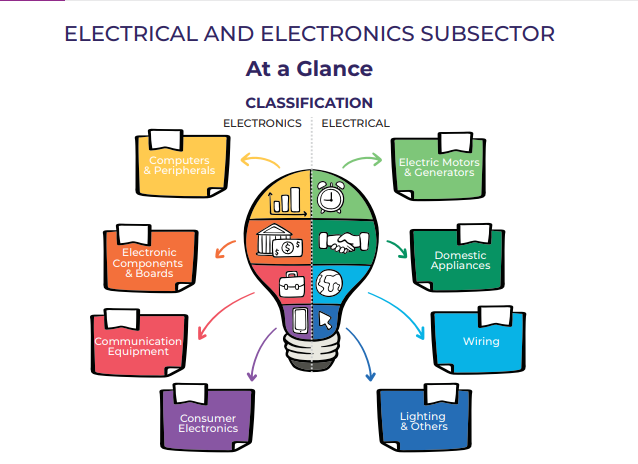

This module describes the skills, knowledge and attitude required to operate and monitor manual and automated manufacturing equipment. It is for students pursuing a Bachelor of Technology in Manufacturing Technology. At the end of this module, the students will be able to properly analyse electrical power circuits, their measurement techniques, electrical machines performance and concepts of electronics technology in the manufacturing process.

- Teacher: NIYONSABA Maximillien

This module is designed to equip manufacturing engineers with engineering economics-related skills. At the end of the module, the learner will be able to apply basic principles of economics, principles of markets for factors of production, techniques of cost estimation and budgeting, and techniques of cash flow analysis in manufacturing processes.

- Teacher: UMUHIRE Jerome

This module highlights essential competences in the mechanics of materials in manufacturing, emphasizing the ability to analyze materials’ properties and behavior, evaluate material formability, apply beam behaviors, and conduct fatigue and failure analysis. These competences enable professionals to make informed decisions, optimize manufacturing processes, and ensure the performance, safety and reliability of manufactured components.

- Teacher: Ndahimana Anastase

- Teacher: Gaspard Bizimungu

At the end of this module, the student will be able to perform industrial product design for manufacturing.

They will be able to Develop design ideas, generate design concepts, make product model simulations, supervise prototype manufacturing activities, and develop industrial documentation.

- Teacher: Ndahimana Anastase

- Teacher: Gaspard Bizimungu